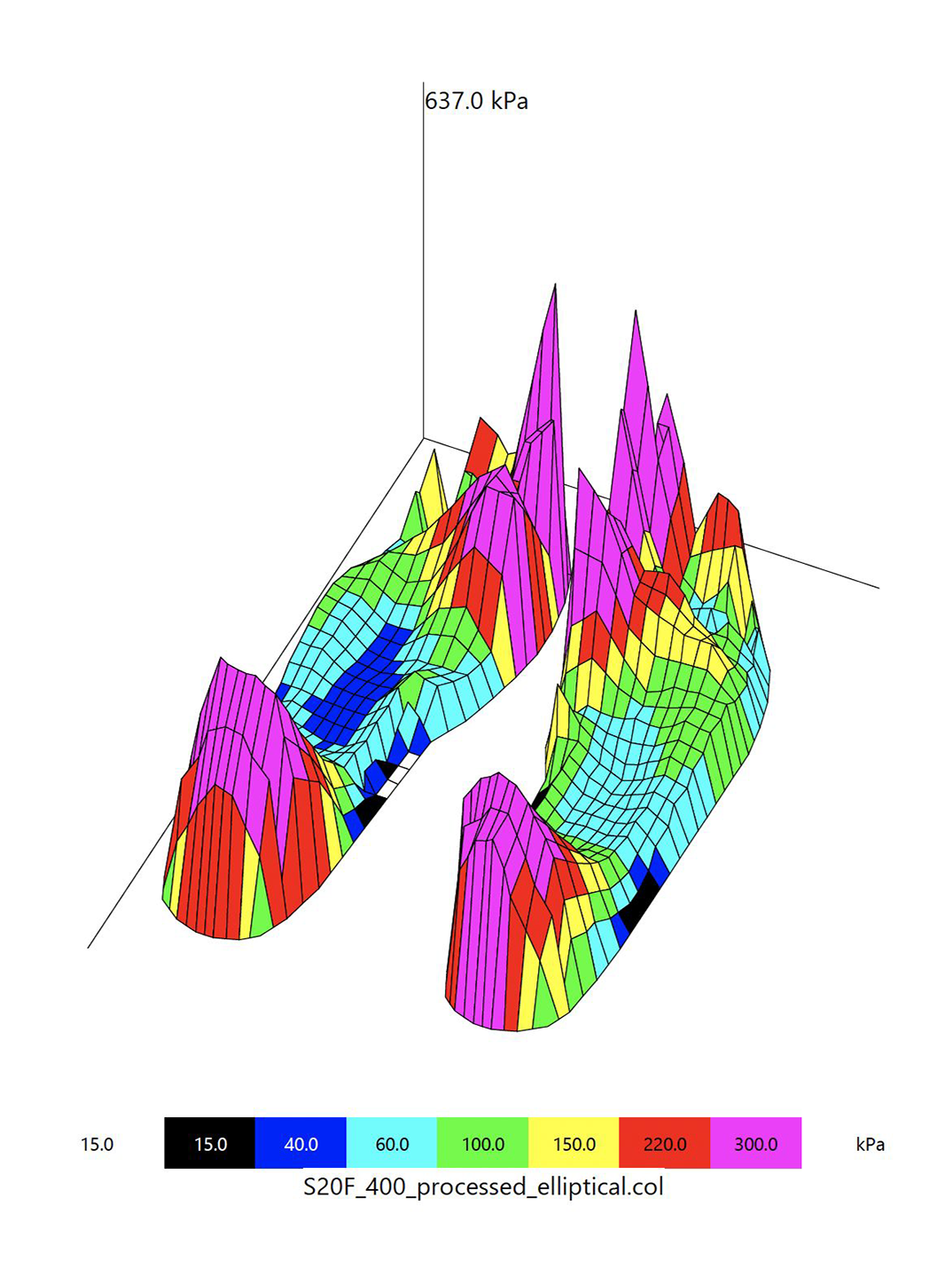

Labor, sacrifice, and displacement are often hidden behind the glamour of world athletics when a nation prepares to host the Olympic Games. Amalgamate is designed to be a unifying ring for natives, staff, supporters, and athletes and is a part of the 5Rings exhibition created by 13 of my classmates and I. Featured at the Olympic Trials in Eugene, Dutch Design Week, and the Greener Manufacturing Expo, 5Rings has been nominated for the Green Product Award. Aside from designing and manufacturing Amalgamate in five material types, I was in charge of data analysis and visualization for the LCA team. I calculated the carbon impact of each of my classmates' rings and developed color-coded categories of display tower stack heights that correlated with the carbon impact for each of the rings. Additionally, I produced graphs representing the overall average carbon impact for each process.

Workflow: Graphic Design, Life Cycle Analysis (LCA), Metalsmithing, Rhino & SolidWorks, Exhibition Design

Guided Question: How might we use data analysis and design to educate the public about material and manufacturing sustainability, while honoring the Olympic Trials in Eugene, OR through the 5Rings exhibition?

I designed one ring and manufactured five versions via stereolithography (SLA) printed resin with dye, multicolor fused deposition modeling (FDM) of polylactic acid (PLA), investment casted silver with enamel, investment casted ancient bronze with powder coating, and 3D printed stainless steel.

I analyzed my classmates' ring LCA data in Excel and SolidWorks Sustainability XPress. Then, I developed a formula to correlate the height of each ring tower to its carbon impact and produced graphs to visualize the average data for all of the rings by material and manufacturing type.